Fouling Factor in Plate Heat Exchangers: never ending story...

During operation with liquids and gases a dirt film may build up on the heat exchanger surfaces . The deposit film is referred to as fouling.

Increased thermal resistance caused by the deposit can normally only be obtained from tests or experience. The fouling factor can be determined as

Rd = 1 / Ud - 1 / U (1)

where

Rd = fouling factor - or unit thermal resistance of the deposit (m2K/W)

Ud = thermal conductance of heat exchanger after fouling (W/m2K)

U = thermal conductance of clean heat exchanger (W/m2K)

(1) can also be expressed as:

Ud = 1 / (Rd + 1 / U)

Typical Fouling Factors

- Alcohol vapors : Rd = 0.00009 (m2K/W)

- Boiler feed water, treated above 325 K : Rd = 0.0002 (m2K/W)

- Fuel oil : Rd = 0.0009 (m2K/W)

- Industrial air : Rd = 0.0004 (m2K/W)

- Quenching oil : Rd = 0.0007 (m2K/W)

- Refrigerating liquid : Rd = 0.0002 (m2K/W)

- Seawater below 325 K : Rd = 0.00009 (m2K/W)

- Seawater above 325 K : Rd = 0.0002 (m2K/W)

The fouling factors to be used in the design of heat exchangers are normally specified by the client based on his experience of running his plant or process to simulate dirt accumulation on the heat transfer surfaces, but if these are not restricted to proper levels they can totally negate any benefits generated by skilful design. The fouling factor represents the theoretical resistance to heat flow due to a build up of a layer of dirt or other fouling substance on the tube surfaces of the heat exchanger but they are often overstated by the end user in an attempt to minimise the frequency of cleaning. In reality they can, if badly chosen, lead to increased cleaning frequency.

Fouling mechanisms vary with the application but can be broadly classified into four common and readily identifiable types.

Common types of fouling

- Chemical fouling; when chemical changes within the fluid cause a fouling layer to be deposited onto the tube surface. A common example of this phenomenon is scaling in a kettle or boiler caused by "hardness" salts depositing onto the heating elements as the solubility of the salts reduce with increasing temperature. This is outside the control of the heat exchanger designer but can be minimised by careful control of the tube wall temperature in contact with the fluid. When this type of fouling occurs it must be removed by either chemical treatment or mechanical de-scaling processes (wire brushes or even drills to romove the scale or sometimes high pressure water jets)

- Biological fouling; this is caused by the growth of organisms within the fluid which deposit out onto the surfaces of the heat exchanger. This is once again outside the direct control of the heat exchanger designer but it can be influenced by the choice of materials as some, notably the non-ferrous brasses, are poisonous to some organisms. When this type of fouling occurs it is normally removed by either chemical treatment or mechanical brushing processes.

- Deposition fouling; this is when particles contained within the fluid settle out onto the surface when the fluid velocity falls below a critical level. This is to a large extent within the control of the heat exchanger designer as the critical velocity for any fluid/particle combination can be calculated to allow a design to be developed with minimum velocity levels higher than the critical level. Mounting the heat exchanger vertically can also minimise the effect as gravity would tend to pull the particles out of the heat exchanger away from the heat transfer surface even at low velocity levels. When this type of fouling occurs it is normally removed by mechanical brushing processes.

- Corrosion fouling; this is when a layer of corrosion products build up on the surfaces of the tube forming an extra layer of, usually, high thermal resistance material. By careful choice of materials of construction the effects can be minimised as a wide range of corrosion resistant materials based on stainless steel and other nickel based alloys are now available to the heat exchanger manufacturer.

One of the most misunderstood items in the heat exchanger schedule is the fouling factor with different types of unit.

Shell and Tube Heat Exchanger Fouling Factors

Engineers are often faced with interoffice scheduling traditions. While we were working with a local engineer on a heat exchanger application, she asked why the office always specified a .0005 fouling factor on SU heat exchangers. Let’s look at what heat exchanger fouling factors are and what choices the engineer has regarding them.

What Is a Fouling Factor in Shell and Tube Heat Exchangers?

Fouling factor is a numerical allowance for possible coating of the tubes by dirt or precipitate in the heated or cooled fluid. Fouling can occur inside the tubes or outside the tubes. It forms a very small coating that adds resistance to heat transfer. The fouling factor adds surface area to the heat exchanger so it can continue to meet the required capacity even though the tubes are coated or fouled.

Why Are Fouling Factors Expressed in Thousandths or Ten Thousandths?

Let’s look at basic heat transfer and the formula we all know well:

Q = U value x Area x LMTD

The BTUH required (Q) and the log mean temperature difference (LMTD) are fixed by the design capacities. The variables are the U value and the surface area of the heat exchanger. As the U value becomes smaller, the surface area required to do the job goes up.

The U value is the inverse of the resistance in the heat exchanger to heat transfer. The U value is very dependent on the fluid type, the velocity, and the materials of construction. It is not unusual for the U value of a steam-to-water shell and tube heat exchanger for hydronic heating to be in the 500 to 1000 range before adding fouling. This is a high U value because condensing steam carries a higher temperature and a large BTU per pound. Let’s assume the number is 800. The inverse, resistance, would be .00125. If we add a fouling factor of .0005 to it, the result is .00175 and the U value becomes 571. The surface area required goes up by 40%.

In a water-to-water shell and tube heat exchangers , the U value is more like 300 to 700.

What Fouling Factors Should I Use?

In closed hydronic heating systems, dirt and poor water quality can affect many products other than the heat exchanger. For this reason, we go to great lengths to make sure those systems are clean. Clean systems promote less fouling in shell and tube heat exchangers.

The U value is also greatly affected by the fluid type and temperature. Glycols will lower the U value. Lower temperatures will lower the U value. Material of construction can change the U value.

The old rules of thumb for .001 fouling factors is just too conservative for today’s more precise methods of determining capacities. In addition, the larger fouling factor provides a solution with a larger heat exchanger that isn’t “green.” You could use .0008 for water-to-water heat exchangers. This is a safe overall rule of thumb for liquid-to-liquid shell and tube selections with water. .

What Fouling Factors Should I Use for Plate Heat Exchangers?

PHE FF must be 1/10 of Shell&Tube HEX FF as finally API 662 recommended. There is confusion among process engineers on FF to be used in PHE and often EPC Contractors data sheets are mentioning FF for S&T HE's. Investigations demonstrated that these values are not giving good results in PHE since they often results in oversized units with premature fouling due to reduced velocity and turbolence.

The advantages of compact heat exchangers over shell and tube ones at a glance:

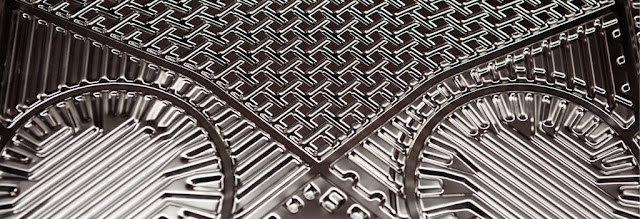

larger heat transfer coefficients smaller heat transfer surfaces required lower fouling due to high fluid turbulences (self-cleaning effect) significantly smaller required installation and maintenance space lighter weight simplified cleanability especially for PHE lower investment costs closer temperature approach pure counter-flow operation for PHE

Deposits create an insulating layer over the surface of the heat exchanger that decreases the heat transfer between fluids and increases the pressure drop. The pressure drop increases as a result of the narrowing of the flow area, which increases the gap velocity (Wang et al., 2009). Therefore, the thermal performance of the heat exchanger decreases with time, resulting in an undersized heat exchanger and causing the process efficiency to be reduced. Heat exchangers are often oversized by 70 to 80%, of which 30 to 50% is assigned to fouling. While the addition of excess surface to the heat exchanger may extend the operation time of the unit, it can cause fouling as a result of the over-performance caused by excess heat transfer area; because the process stream temperature change greater than desired, requiring that the flow rate of the utility stream be reduced.

As a result of the effects of fouling on the thermal and hydraulic performance of the heat exchanger, an additional cost is added to the industrial processes. Energy losses, lost productivity, manpower and cleaning expenses cause immense costs. The annual cost of dealing with fouling in the USA has been estimated at over $4 billion (Wang et al., 2009). The manner in which fouling and fouling factors apply to plate exchangers is different from tubular heat exchangers. There is a high degree of turbulence in plate heat exchanger, which increases the rate of deposit removal and, in effect, makes the plate heat exchanger less prone to fouling. In addition, there is a more uniform velocity profile in a plate heat exchanger than in most shell and tube heat exchanger designs, eliminating zones of low velocity which are particularly prone to fouling. Figure 2 shows the fouling resistances for cooling water inside a plate heat exchanger in comparison with fouling resistances on the tube-side inside a shell and tube heat exchanger for the same velocity. A dramatic difference in the fouling resistances can be seen. The fouling resistances inside the PHE are much lower than that inside the shell and tube heat exchanger.

Fouling inside heat exchanger can be reduced by:

- Appropriate heat-exchanger design

- Proper selection of heat-exchanger type

- Mitigation methods (mechanical and/or chemical)

- Heat exchanger surface modification/coating

I got personal experience on this FF discussion: a large Oil & Gas EPC in Italy told me to design with standard FF on Monoethanolamine in a Gas Sweetening job, in spite of my argumentation. After installation I got a phone call claiming unit not performing according to specs. I suggested to open PHE, take away 50% of plates and restart.

Performance in this case was 100% perfect.

EPC Contractors data sheets already are mentioning 10% oversurface, then 10% on flow rate and duty, so that keeping FF 10 time larger then required (remenber API 662 recommendations) will reduce velocity in flow channels and our common Friends Reynold, Nusselt and Prandtl will be disappointed...

Therefore Heat Transfer Specialist don't use Fouling Factor values of Shell& Tube HEX when you are dealing with PHE's! Overdimension is a great mistake that can have huge impact on unit performance!

Wonderful blog, Which help us to understand information easily and fast. Keep sharing more info on this stainless steel 316 wire mesh Visit Mcneil Instrument to more relevant services.

RispondiElimina