INSPECTING PLATE HEAT EXCHANGERS USING DIFFERENT DYE PENETRANT TESTING

Procedure 1

After cleaning, the plates are thoroughly inspected for corrosion, holes or cracks by dye penetrant testing. Using this method, which originated in the aviation industry, even the finest hairline cracks in the plate can be made visible.

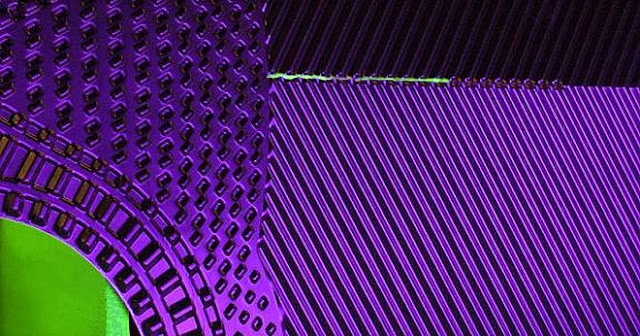

After cleaning, the entire surface of each single plate is sprayed with a fluorescent paint. After the appropriate exposure time, the plate is rotated and thoroughly inspected under UV light in the darkened test room. Damaged plates are marked accordingly and sorted out. Flawless plates are now cleaned again by means of high pressure.

The ultraviolet test is used upon request, usually specialty applications where fluid mediums can only detected under UV light.

Worth mentioning that paint used in UV test is vegetable and biodegradable, so that after washing liquids can be discharged in civill drain without pollution implications.

Procedure 2

100% Dye-Testing is standard for locating cracks, pinholes, or failures. With red dye-penetrant saturating the plate surface, and white developer solution covering the reverse side, test is capable of detecting even miniscule imperfections. Consider that 90% of plates tested have a 10% fail rate. Basically, random checking of 10-20% cannot eliminate all bad plates. Although Dye-Testing is the most time consuming and expensive method for leak detection, many people chooses the process for its reliability and effectiveness. Early discovery of plate defects alleviates cross-contamination concerns, saving costly down-time in the future.

Advantage of red dye-penetrant procedure is that is widely used in Oil & Gas applications to check Shell & Tube Heat Exchangers, Pressure Vessels, Valves, Manifold basically when weldings are involved.

Furthermore red dye-penetrant procedure meet ASME Code, API and 3-A Standards.

Negative feature of red-dye paint and white paint is high content of components that are not pollution free, so that exhausted liquid after washing can not be discharged in the drain, but collected and shipped to proper chemical treatment.

Conclusions:

If Plate Heat Exchanger application is Oil & Gas, Refinery, Petrochemical with ASME VIII Div.1 Code with U Stamp and EPC Contractors are involved, red dye-penetrant procedure is a must to have, otherwise Third Party Inspectors will be in trouble to approve unit.

If you are in a Service Centre dedicated to Plate Heat Exchangers in the middle of the town, with expert personnel, able to detect small cracks or pitting holes just carefully watching plate in the dark with fluorescent paint, UV light is the best way to operate, in green way without issues related to liquid discharge.

Commenti

Posta un commento