Methods for monitoring the technical condition of plate heat exchangers

1. Introduction The task of monitoring in the technological processes of the oil and gas industry is to prevent the potentially dangerous causes of possible accidents and to prevent the failure of technological equipment, which ensures the efficient operation of enterprises in the given modes, thereby improving the quality of products and labor productivity [1-5]. Methods of monitoring the technical condition of heat exchange equipment, namely plate heat exchangers, are based on the control and monitoring of heat exchange equipment using pressure and temperature sensors. After obtaining such indirect monitoring results, the condition of the heat exchanger as a whole and its internal part, including the plates, is estimated using correlation [6-11]. Cleaning this type of equipment is very time-consuming and financially expensive. It is not always possible to objectively evaluate and decide on the need for cleaning of equipment. It is a method in which, in real time and on a working plate heat exchange equipment, it is possible to assess the condition of the plates for deposits, their thickness with a high degree of accuracy and subsequently use such data to decide on repair and restoration operations. Therefore, the aim of the work is to develop a method for determining the optimal amount and location of instrument on the working surfaces of a plate heat exchanger for determining the thickness of deposits.

2. Description of the method for determining the number and installation location of thermoelectric modules (Peltier elements) During the operation of heat exchangers on the inner surfaces of the heat transfer plates, various kinds of contamination occur that impede efficient operation [12, 13]. The main types of pollution of plate heat exchangers are: - crystallization (most often in the form of scale formation);

- sedimentation (deposition of clay, sand, rust);

- growth of organic products and polymers;

- coking of hydrocarbons. Contamination of the plates in the plate heat exchanger can occur according to two possible schemes, shown in Figure 1.

The main methods for monitoring and diagnosing the effective operation of technological equipment: - Monitoring by operating personnel (visual, tactile, aural); - Monitoring and diagnostics using technical devices (using various pressure and temperature sensors, video surveillance, etc.). In addition to these methods, a method is proposed that is based on the laws of changes in voltage on a thermoelectric module depending on the thickness of the deposit. But the disadvantage of this

method is the lack of recommendations for the precise installation of thermoelectric modules on a heat exchanger [14-16].

For the study, 15 plates with a surface area of 1 m2 were used. In terms of intensity, deposits were divided into 3 groups: strong (S3), medium (S2), and without deposits (S1). Next, an analysis was made of the size of these deposits and the maximum and minimum spot sizes were revealed (Table 1).

After analyzing the obtained data, it is concluded that deposits on the plates are formed as a solid "spot" and small inclusions. Further, to highlight the most common places of contamination on the plates, each plate is 200 points (Figure 2).

On the tables reflecting deposits on the plates, deposits are indicated by groups: 0 - no deposits, 5 - medium deposits, 10 - strong deposits (require cleaning).

A total table with average values of deposit thicknesses, on which zones of severe pollution can be seen, is shown for 15 test plates (Figure 3).

A clear picture of deposits with average deposit thicknesses is shown in the deposit distribution chart (Figure 4).

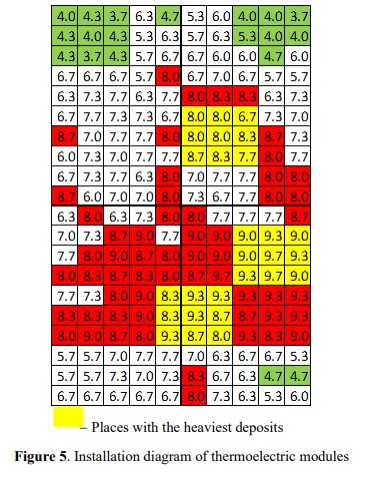

After obtaining a clear picture of the average distribution of deposits on plate heat exchangers, installation locations are selected for thermoelectric modules in the predicted strongest areas of deposits and the optimal number of elements is determined for monitoring the technical condition of the plate heat exchanger (Figure 5).

3. Conclusion The proposed method for selecting the installation locations of thermoelectric modules allows you to objectively assess the technical condition of plate heat exchangers and reduce the complexity of the repair of technological equipment.

Based on this method, it becomes possible to develop a system for diagnosing and monitoring deposits, which is a set of devices and mechanisms that determine the thickness of pollution on a heat exchanger plate of a plate heat exchanger.

The results can be used to develop a method of automatic chemical cleaning of the apparatus when the threshold value of the deposition thickness is reached and to develop a device that allows for realtime measurement of the deposition thickness on operating heat-exchange equipment.

References

[1] Guo Y, Lu Y, He X and Zhang T 2019 Advances in Intelligent Systems and Computing 885 917- 927

[2] Shishkin A N, Timashev E O, Solovykh V I, Volkov M G and Kolonskikh A V 2019 Oil Industry [in Russian – Neftyanoe Khozyaystvo] (3) 7-12

[3] Robles-Durazno A, Moradpoor N, McWhinnie J and Russell G 2018 2018 Int. Conf. on Cyber Security and Protection of Digital Services, Cyber Security 2018 8560683

[4] Mukhametzyanov Z R 2018 IOP Conference Series: Materials Science and Engineering 451(1) 012077

[5] Kulakov P A, Rubtsov A V, Afanasenko V G, Zubkova O E, Ivanova K K and Sharipova R R 2020 Bulletin of the Tomsk Polytechnic University, Geo Assets Engineering 331(1) 97-105

[6] Saranya S N, Sivakumar V M, Thirumarimurugan M and Sowparnika G C 2017 Proc. of 2017 11th Int. Conf. on Intelligent Systems and Control, ISCO 2017 7856032 439-443

[7] Demirskyy O, Kapustenko P, Arsenyeva O, Tovazhnianskyi V and Khusanov A 2018 Computer Aided Chemical Engineering 43 289-290

[8] Kapustenko P O, Demirskiy O V, Tovazhnyanskyi V I, Arsenyev P Y and Arsenyeva O P 2018 Chemical Engineering Transactions 70 109-114

[9] Chekardovsky S M, Mironov V V, Guseva K P and Bocharova A A 2018 IOP Conference Series: Earth and Environmental Science 194(6) 062007

[10] Jiang H, Dong S, Li A and Meng F 2019 Energy Procedia 158 1850-1855

[11] Xu Y 2019 AIP Conference Proceedings 2154 020067

[12] Potirniche G P and Barannyk L L 2019 Energy 185 262-273

[13] Hand C T and Peuker S 2019 Heliyon 5(10) e02752

[14] Xu Z, Sun A, Han Z, Yu X and Zhang Y 2019 Powder Technology 355 145-156

[15] Sharma A and Macchietto S 2019 Computer Aided Chemical Engineering 46 1483-1488

[16] Guo Y, Wang F, Jia M and Zhang S 2018 Chemical Engineering Research and Design 138 418- 432

Z R Mukhametzyanov, P A Kulakov and A V Rubtsov Ufa State Petroleum Technological University, 1, Kosmonavtov str., Ufa, 450062, Russia E-mail: kulakov.p.a@mail.ru

Content from this work may be used under the terms of theCreative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

High-Tech and Innovations in Research and Manufacturing (HIRM-2020) Journal of Physics: Conference Series 1582 (2020) 012054 IOP Publishing doi:10.1088/1742-6596/1582/1/012054

Commenti

Posta un commento