Flow Maldistribution in Plate Heat Exchangers (Part 2)

Geometrical optimization

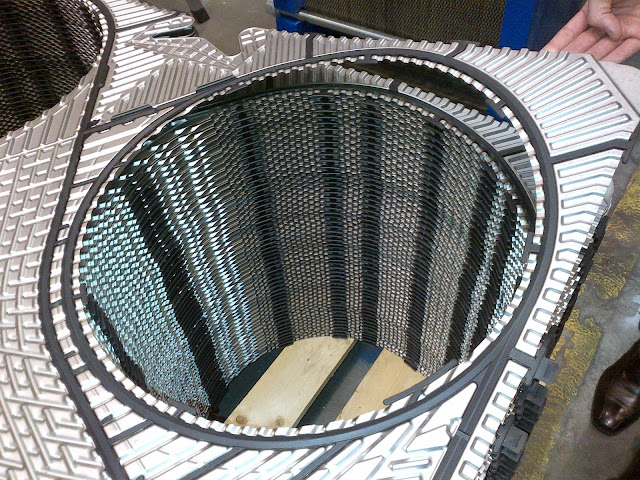

To decrease the intensity of the flow maldistribution, a number of geometrical optimizations to the inlet header collector were proposed. The main goal was to force the fluid stream to flow into the channels with a more uniformly distributed mass flow. The investigated geometrical changes are schematically shown in Figure 3 and listed in Table 4. Their simplicity makes straightforward application possible in a real PHE.

Table 4. Considered geometrical optimizations of the PHE.

The order in the table matches the order of the ketches in Figure 3.

Table 4. Considered geometrical optimizations of the PHE.

The order in the table matches the order of the ketches in Figure 3.

In the cases: 2str, 3str, 4str, 2str2, 3str2, 4str2, TW-top, TW-alt, additional baffles are introduced to the bottom header of the PHE to force a separation of the inletting fluid. Cases: 5_3, 10_6, 20_12, 25_15, 5_59, 10_59 assume the gradual reduction of the inlet cross-section area in consecutive channels. The first digit in the X_Y name indicates the percentage of the gradual opening of the

channels and the second digit indicates the number of channels with inlet openings of the same size, Fig.4

Figure 3. Sketches of considered geometrical modifications. From top to bottom: org, org3, 2str, 3str,

4str, 2str2, 3str2, 4str2, TW-top, TW-alt, 5_3, 10_6, 20_12, 25_15, 5_59, 10_59. The percentage indicates the size of inlet opening. For detailed explanation see Table 4.

Mathematical model and numerical implementation

The mathematical model used to calculate the flow was based on incompressible Navier-Stokes equations. The numerical model was built in the OpenFOAM CFD toolbox (14) and solved using one of its standard solvers simpleFOAM. SimpleFOAM uses the SIMPLE (Semi-Implicit Method for Pressure-Linked Equations) algorithm to couple momentum and pressure equations.

The numerical mesh was checked by mesh independence studies. Finally, a uniform hexahedral mesh was used with ~14 000 000 computational cells. Every flow channel had 40 mesh cells in its width direction.

Boundary conditions assumed a zero gradient for pressure and a uniform flow at the inlet to the PHE (with velocity value to assure the desired Rec), constant pressure and zero gradient condition for velocity at the outlet. The mixing, throttling and dividing baffles were treated as walls (no-slip condition and zero gradient condition for pressure).

RESULTS

The evaluation of the intensity of the flow distribution was based on the mass flow in individual channels and calculated at half the height of the PHE. To compare the results between different Rec numbers, a mass flow ratio (MFR) coefficient was defined as: 𝑀𝐹𝑅𝑖=𝑚𝑖̇/𝑚̇𝑎𝑣𝑒, where 𝑚̇𝑖 represents mass flow in the i-th channel and 𝑚̇𝑎𝑣𝑒 is the theoretical average mass flow in the channel, assuming perfect distribution of the flow.

To evaluate and compare the results for different geometrical modifications, the degree of non-uniform flow s was defined as an average absolute deviation:

Based on Eq. (4), the parameter for the degree of maldistribution was defined as: 𝐷𝑀=1−𝑠𝑠𝑤⁄, where sw is the worst possible maldistribution calculated using Eq. (4) with the assumption that the whole flow goes through the first channel of the PHE. The value of DM changes from 0 to 1, where 1 means a uniform mass flow in every channel (no maldistribution).

Figure 4. shows the effect of Rec on the intensity of maldistribution. It compares the MFR coefficient for the developed 2D model (org3 geometry, Table 4.) in the considered range of Rec= (50, 100, 250, 500, 1000) and, additionally, shows the MFR for a basic 2D geometry (without mixing and throttling baffles, org geometry, Table 4.). The value of DM for these results are presented in Table 5.

Figure 4. Comparison of flow maldistribution of org geometry (top) and org3 geometry (bottom) for various Rec.

The introduction of mixing and throttling baffles can be observed to have a crucial impact on the results. The differences between the org and org3 models are related to an inconsistent pressure drop balance to the original 3D geometry (in the case of the org model). The pressure loss in the header of the org is too high in relation to the pressure drop in the channels, and the flow chooses “the easiest way” through the first few channels.

The importance of the ratio of the pressure losses in the PHE header and the channels is further examined by introducing various modifications to the org geometry such as changing the channel inlet cross-section, as seen in cases: 1_3, 2_6, 4_12, 5_15, 5_59, 10_59. From the results shown in Figures 5 and 6, and Table 5, it can be deduced that this is a crucial factor in the creation of flow maldistribution. Provoking a higher pressure drop in the channels results in a smaller flow maldistribution. This is especially visible in cases 5_59 and 10_59 where the pressure drop in the channels is substantially elevated by leaving only 5% or 10% of the original inlet cross-section area uncovered respectively. It should be noted that the implementation of the above solution in a real PHE is not advisable because the pressure drop introduced would be too high. But this can be solved by implementing a certain strategy, which is used in cases 5_3, 10_6, 20_12 and 25_15. Here, additional resistance is highest for the initial channels and decreases with distance. These solutions minimize flow maldistribution and introduce much lower cumulative additional resistance, compared to the modifications in cases 5_59 and 10_59.

In the case of a real PHE, gradual change in channel resistance can be achieved by assembling the PHE from a different type of plates, e.g. chevron patterns with a different angle.

Figure. 5. Flow maldistribution in org geometry and different geometrical modifications, Rec = 50.

Figure. 6. Flow maldistribution in org geometry and different geometrical modifications, Rec = 1000.

Figures 7 and 8, and Table 6 summarize the results for the considered geometrical modifications introduced in the full 2D model, org3. Solutions with additional horizontal baffles can be observed to reduce the flow maldistribution significantly for the whole range of the considered Rec. Cases with a lower number of horizontal dividers are more optimal. This is related to the alternating the pressure balance of the PHE. Every additional divider creates a smaller hydraulic diameter and a larger pressure drop in the PHE header. Opposite to this, in the case of vertical baffles (TW-top and TW-alt), the flow maldistribution becomes even greater. The vertical obstacles create more turbulence in the header and the overall performance of the PHE seem to be less stable. Consequently, this causes a higher pressure drop in the PHE header too.

Figure. 7. Flow maldistribution in org3 geometry and different geometrical modifications, Rec = 50.

Figure. 8. Flow maldistribution in org3 geometry and different geometrical modifications, Rec = 1000.

Figures 9 and 10 show the flow, represented by the velocity magnitude of the entire considered PHE. In Figure 9, a magnified region showing the detailed flow in individual channels is depicted in order to illustrate the influence of mixing baffles. Figure 10 shows the flow in part of the PHE header and the inlets to the channels in order to illustrate the influence of throttling baffles. The fluid is visibly seen to enter the channels through only a small part of the inlet cross-section, which is not blocked by throttling baffles.

Figure 10. Magnified region of org3 geometry showing the velocity magnitude field at channels inlet, Rec = 1000.

CONCLUSIONS

The presented work is focused on developing an efficient and fast numerical methodology for comprehensive research related to PHE. The robust transformation of the real 3D geometry of the PHE into its 2D representation was a key feature in order to significantly reduce computation time but also provide trustworthy results. The transformation reduced the number of computational mesh cells by two orders of magnitude. This made it possible to perform a significant number of calculations, and to explore a wide range of parameter space and a number of various geometrical modifications. An analysis of the results provided a potentially meaningful insight into more preferable geometrical optimizations.

One of the main factors responsible for the strength of the flow maldistribution was shown to be the ratio of pressure drop in a PHE header and its channels. If the pressure drop in the channels is artificially enlarged, flow maldistribution becomes smaller. This suggests that PHE with gradually changing values of pressure loss in consecutive channels can minimize maldistribution. Practically, this can be archived by assembling a PHE from different plates, e.g., with chevron patterns of different angles. In the case of a typical PHE assembled from the same type of plates, a reasonable solution is to introduce horizontal baffles. This divides the inletting flow into several streams and directly delivers it into further sections of the PHE. More optimal solutions are with smaller number of horizontal dividers. Every additional divider creates a smaller hydraulic diameter and, consequently, a larger pressure drop in the PHE header.

In the case of introducing vertical baffles into the PHE header, flow maldistribution becomes even greater than for a PHE without any baffles. The vertical obstacles intensify the turbulence and the overall performance of the PHE seems to be less stable. Consequently, this causes a higher pressure drop in the PHE header too.

The above conclusions should also hold in the case of two-phase flows or flows with a phase-change. The proposed methodology of 2D transformation is universal and can be applied with different mathematical models, including flows with a phase-change and various types of fluids, e.g., LNG.

ACKNOWLEDGEMENTS

The presented work has been undertaken in the framework of the Poland Taiwan scientific cooperation, as a part of the project: “Development of plate heat exchangers for liquid inert gas vaporization, and the modelling of the two phase flow in heat exchangers” (PHEVAP), financed by The National Center for Research and Development, Poland, No. PL-WTIII/7/2016.

The work has been partly supported by statutory funds from the Polish Ministry for Science and Higher Education No. 0401/0168/17.

Calculations have been carried out using resources provided by the Wroclaw Centre for Networking and Supercomputing (http://wcss.pl), grant No. 460. The authors would like to thank Chia-Luen Lee for her careful proofreading and language corrections.

NOMENCLATURE

m refrigerant mass flow, kg/s

Nc number of PHE channels

Ac cross-section area of a channel, m2

Δp pressure drop, Pa

μ dynamic viscosity, N·s/ m2

D hydraulic diameter, m

H height of inlet/outlet of the 2D PHE

h length of a throttling baffle, mm

s average absolute deviation

ζ local pressure loss coefficient

MFR mass flow ratio

DM degree of maldistribution

Subscripts

ave average

b baffle

c channel

h header

in inlet

out outlet

w worse case

i i-th channel of PHE

3D three-dimensional

2D two-dimensional

REFERENCES

(1) Mueller, A.C. and Chiou, J.P. (1988): “Review of various types of flow maldistribution in heat exchangers”. Heat Transfer Engineering, Vol. 9, pp. 36-50.

(2) Pacio, J.C. and Dorao, C.A. (2010): “A study of the effect of flow maldistribution on heat transfer performance in evaporators”. Nucl. Eng. Des., Vol. 240, pp. 3868-877.

(3) Jung, J. and Jeong, S. (2007): “Effect of flow mal-distribution on effective NTU in multi-channel counter-flow heat exchanger of single body”. Cryogenics, Vol. 47, pp. 232-242.

(4) Pawar, N. and Maurya, R.S. (2012): “Flow maldistribution in a simplified plate heat exchanger model-a numerical study”. Appl. Mech. and Mater., Vol. 110, pp. 2529-2536.

(5) Wang, L., Christensen, R. and Sunden, B. (2000): “An experimental investigation of steam condensation in plate heat exchangers”. Int. J. of Heat Exch., Vol. 1, pp. 125-150.

(6) Vist, S. and Pettersen, J. (2004): “Two-phase flow distribution in compact heat exchanger manifolds”. Exp. Therm. Fluid Sci., Vol. 28, pp. 209-215.

(7) Sterner, D. and Sunden, B. (2006): “Performance of Plate Heat Exchangers for Evaporation of Ammonia”. Heat Transfer Eng., Vol. 27, pp. 45-55.

(8) Lin, Y.H., Li, G.C and Yang, C.Y. (2015): “An experimental observation of the effect of flow direction for evaporation heat transfer in plate heat exchanger”. Appl. Therm. Eng., Vol. 88, pp. 425-432.

(9) Raul, A., Bhasme, B. and Maurya, R. (2016): “A numerical investigation of fluid flow maldistribution in inlet header configuration of plate fin heat exchanger”. Energy Procedia, Vol. 90, pp. 267-275.

(10) Peng, X., Liu, Z., Qiu, C. and Tan, J. (2016): “Effect of inlet flow maldistribution on the passage arrangement design of multi-stream plate-fin heat exchanger”. Appl. Therm. Eng., Vol. 103, pp. 67-76.

(11) Yuan, P., Jiang, G., He, Y., Yi, X. and Tao, W. (2013): “Experimental study on the performance of a novel structure for two-phase flow distribution in parallel vertical channels”. Int. J. Multiphase Flow, Vol. 53, pp. 65-74.

(12) Malecha, Z., Pluszka, P. and Brenk, A. (2017): “Numerical investigation of cryogen regasification in a plate heat exchanger”. IOP Conf. Ser.: Mater. Sci. Eng., Vol. 278, pp. 1-8.

(13) Czetwertyski, E. and Utrysko, B. (1969): “ Hydraulika i hydromechanika”. 3rd Edition, PWN Warszawa. (14) Weller, H.G., Tabor, G., Jasak, H. and Fureby, C. (1998): “A tensorial approach to computational continuum mechanics using object-oriented techniques”. Comput. Phys., Vol. 12, pp. 620-631.

Credits:

Ziemowit Miłosz Malecha

Wroclaw University of Science and Technology | WUT · Department of Cryogenic, Aviation and Process Engineering

Ziemowit Miłosz Malecha

Paweł Płuszka

Paweł Płuszka

Commenti

Posta un commento