Which Heat Exchanger Is Best? The Three Main Types Explained...

Heat exchangers all work by passing a hot fluid and a cold fluid across opposite sides of a piece of metal. The heat from one fluid passes across the metal (which is thermally conductive) into the other fluid without the fluids making contact. High fluid velocity, high turbulence, high surface area and a large temperature differential all contribute to more efficient heat transfer. However, different designs are more efficient than others depending on the application.

There are three common kinds of heat exchangers. They can all be effective in a variety of heat transfer applications, but optimizing efficiency, cost and space depends heavily on the particular process in which the heat exchanger is installed. This article explains the basic qualitative differences between common heat exchangers to help you decide which is most appropriate for your application.

Shell and Tube Heat Exchangers

|  |

Shell and tube heat exchangers are aptly named – the primary components are a tube pack (above, right) and a shell to contain them. One fluid goes through the tubes, and the second goes through the larger shell, surrounding the tubes. The prototypical shell and tube heat exchanger has only one inner tube, and is typically used to teach engineering students the basic concept of a heat exchanger. However, in practice, a pack of smaller tubes is much more effective because it greatly increases the heat transfer surface area (and has a minor positive effect on turbulence to boot).

The shell and tube heat exchanger in the photo above has about twelve times the efficiency than a hypothetical single-tube heat exchanger of the same size. However, there is a disadvantage to smaller tubes – if the fluid in your application is very viscous or has particulates, it can foul up the tube and undermine the heat transfer process.

Shell and tube heat exchangers dominated the heat exchanger market up until the early 21st century, as plate heat exchangers began to replace them in the oil and HVAC industries. Due to their simple design, they also hold a prominent place in engineering curricula around the globe. They have many advantages that helped them earn those achievements. First, they’re relatively cheap – they’re essentially just a bunch of tubes. Also, due to their hydro- and aerodynamic design, they can support higher operating temperatures and pressures than your typical plate heat exchanger, which, due to its compactness, has to change the direction of flow many times per cycle. This also means that the pressure drop from input to output is smaller, which can save on energy costs.

Despite the advantages, plate heat exchangers are becoming preferred due to better heat transfer (we’ll see why in a moment), easier maintenance and cleaning, modularity and compactness.

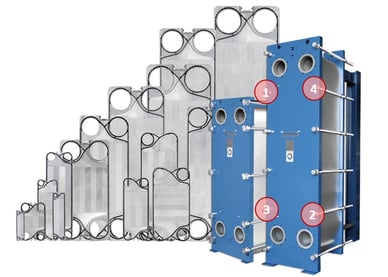

Plate and Frame Heat Exchanger (Plate Heat Exchangers)

|  |

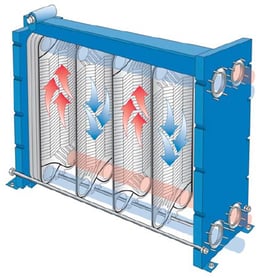

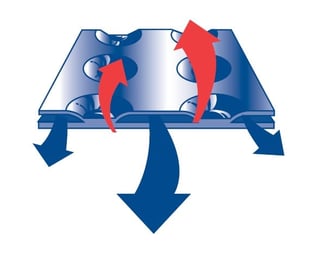

Plate heat exchangers are constructed with a series of plates held together in a large frame. There are two inputs and two outputs, and the spaces between plates alternate between the two liquids (hot, cold, hot, cold, etc. as shown above, right). This design lends itself to very high heat transfer efficiency due to large surface area – much higher than a shell and tube heat exchanger taking up similar space. Plate heat exchangers are also much easier to clean and maintain, because they’re designed to be relatively easy to disassemble and inspect. Also, if there is a defect in a plate, you can simply remove two plates and put the unit right back in service at slightly lower capacity while you wait for replacements. Shell and tube heat exchangers do not share this luxury.

While all plate heat exchangers have corrugated plates, they can differ by how they seal the plates together. In ascending order of leak resistance (and price), plate heat exchangers can be gasketed, brazed or welded. Gaskets, while more susceptible to failure under pressure, are inexpensive and easy to replace. They also offer the indispensable benefit of modularity – a gasketed plate heat exchanger can be completely disassembled, and plates can be added to increase capacity at any time. If a plate heat exchanger is brazed or welded, it’s very difficult and expensive to add plates after the fact. In general, gasketed plate heat exchangers are preferred in industrial settings where flexibility is paramount. Welded plate heat exchangers are rare due to the increased cost, but brazed plate heat exchangers are common in HVAC settings where replacement is easier than maintenance.

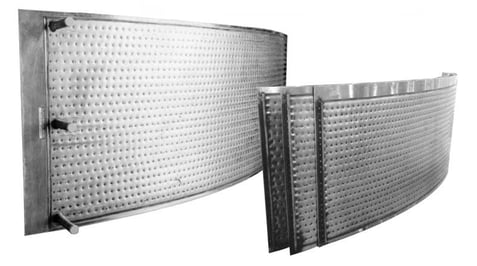

Dimple Plate/Plate Coil Heat Exchanger

|  |

Although its market share is much less than that of the previous two categories, dimple plate/plate coil technology is the best solution for applications where one of the fluids isn’t moving. It’s also useful in retrofit applications, such as waste heat recovery that wasn’t accounted for in the initial blueprints. In general, this is a good option for passive heating or cooling a storage tank (such as a bright beer tank or dairy tank) where refrigeration or heating would otherwise be expensive.

The premise is very simple – two steel sheets are spot-welded together, then inflated to make channels between the plates for fluid to flow. Due to its simplicity and low-cost materials, dimple plate/plate coil technology can generally be customized to any particular application. The most prevalent application is tank jackets for beer and dairy tanks, but sections of dimple plate can also be cut to fit inside a tank and submerged in the stored liquid for efficient heat transfer.

Dimple plate/plate coil offers the best of both above kinds of heat exchangers – it’s cheap, customizable and compact, but can withstand incredibly high pressures and temperatures due to design and materials. It can also be added as an afterthought to many industrial processes, most notably to cut energy costs or comply with environmental regulations.

Conclusion

While shell and tube heat exchangers have been the mainstay of industry for many decades, plate heat exchangers are overtaking them in many sectors due to compactness, efficiency and ease of maintenance. For high pressure/temperature applications that rule out the use of a traditional plate heat exchanger, or passive temperature control needs for a storage tank, a customized sheet of dimple plate may be the best solution.

Commenti

Posta un commento