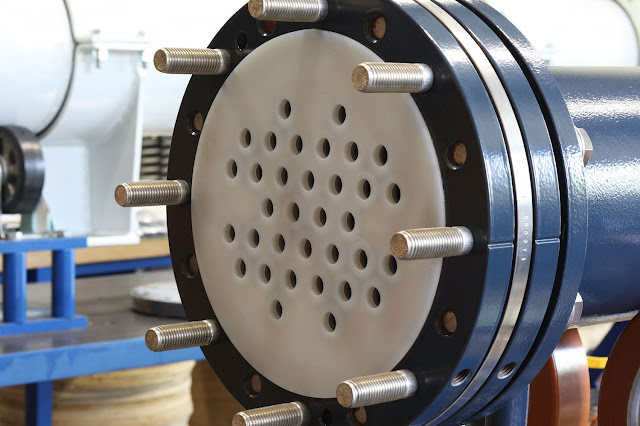

Silicon carbide shell and tube heat exchangers

CORRESIC® Silicon carbide shell and tube heat exchangers are adapted to the cooling, condensation, heating, evaporation and absorption of highly corrosive chemicals. Silicon carbide shell and tube heat exchangers consist in a bundle of silicon carbide tubes inside a shell. One fluid runs through the tubes and another fluid flows over the tubes (through the shell). The heat is transferred by conduction through the silicon carbide tube wall, without direct contact between the fluids.

SiC tubes before assembly in a shell and tube heat exchanger

GAB Neumann only uses pressure less sintered silicon carbide tubes for their upmost corrosion resistance against acids, alkalis and oxidizing media.

SiC heat exchanger with a glass shell

GAB Neumann offers a wide range of materials of construction for the headers and the shell including glass, glass lined steel, PTFE lined steel, carbon steel and stainless steel.

Baffle cage in solid anti-static fiber reinforced PTFE

GAB Neumann offers a wide range of materials of construction for the baffles including stainless steel and PTFE.

Materials:

- CORRESIC® pressureless sintered silicon carbide tubes

- PFA lined tube sheets

- FFKM O’ring gaskets on process side

- FKM or FFKM O’ring gaskets on service side

- Glass lined steel, PTFE lined steel or glass headers or shell on process side

- Carbon steel, stainless steel, glass lined steel, PTFE lined steel or glass headers or shell on service side

- Tie rods, nuts, bolts, washers: stainless steel

Design:

- Universally corrosion resistant silicon carbide (SiC) tubes

- PFA lined tube sheets

- Unique sealing system with FFKM and FKM O’ring gaskets

- Outstanding thermal conductivity

- Adjustable number of tubes, size, length, and number of passes on both sides

- Shell diameter from 100 to 400 mm

- 14, 19 or 25 mm Ø tubes

- 1000 mm to 4500 mm long tubes

- Glass lined steel, PTFE lined steel, or glass for the shell or headers on process side

- Carbon steel, stainless steel, glass lined steel, PTFE lined steel, or glass for the shell or headers on service side

- Unique, ultra-safe and reliable triple tube sheet / double sealing system

Key Features:

- Design pressure: -1 barg (full vacuum) to +10 barg

- Design temperature: -30 to +220°C (-22 to 428°F)

- Heat transfer area: 0,4 to 42 m2 (4 to 452 ft2)

- Design: according to European PED, ASME code, Chinese Pressure Vessel code and other national pressure vessel codes on request

Key Benefits:

- Universal corrosion resistance against acids, alkalis and oxidizing media

- Ultra-corrosive media either in or outside the tubes

- Possibility to have ultra-corrosive media on both sides.

- Superior heat transfer performance thanks to adjustable cross sections on both sides that guaranty a high level of turbulence

- High operational safety

- Highly reliable equipment therefore low cost of ownership and low maintenance cost

- Extreme purity of silicon carbide

- Wide range of materials of construction for the shell and the headers

- Compact and robust design

- Short lead time

- Long lifetime

Optional features:

- Sight glass

- Cleaning in place

- Twisted tapes for performance enhancement

Main applications:

- Condensation of ultra-corrosive and oxidizing vapors in multipurpose units

- Cooling or heating of ultra-corrosive and oxidizing liquids

- Suited for multi and single purpose units

Technical links:

Article ideas very clear . Your writing style is very unique. I very much appreciate the articles you write. Please visit to know Stainless Steel JSLAUS 321 Sheet.

RispondiEliminaM-Kube, a renowned and leading supplier of scientific laboratory equipment, Silicon Carbide Heating Elements and consumables across India. Wide range of products tailored for scientific, research, and medical applications, M-Kube boasts an extensive selection of ceramic lab consumables suitable for high-temperature furnaces and various scientific and chemistry applications.

RispondiEliminaAlumina Tube Suppliers in India

Zirconia Tubes & Rods