Gaskets sealing lifetime in Plate Heat Exchangers

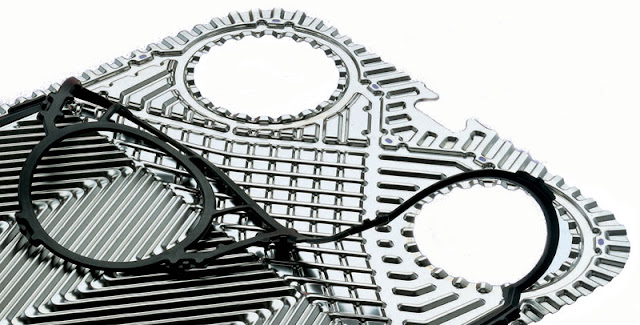

The correct choice of gasket characteristics is crucial to the effective operation of the Plate Heat Exchanger. Since the majority of Plate Heat Exchanger gaskets are manufactured from perishable rubber polymers, they require replacing as the gasket loses the ability to seal through hardening and deterioration.

Vital Properties

Incompressibility - The rubber compounds behaves as if it were a liquid that can change shape but cannot flow, so that after being squeezed it will return to its original vulcanised shape.

Strength - It is strong enough to withstand the forces normally incurred by squeezing into position and being acted upon by pressurised liquid.

Softness - This is adjusted by compounding so that the rubber is strong enough for the application but still soft enough to conform closely to the metal surfaces and provides a seal without undue stresses being applied

Resistance to Fluid - The high molecular weight, cross-linked polymer matrix is resistant to penetration by any fluid of a dissimilar chemical nature to itself.

Resistance to Temperature - One disadvantage of the desired 'rubberness' of the polymer material is the fact that all polymers will only behave as a rubber over a relatively short range of temperature. Thus accurate selection of the compound according to the required temperature range is crucial.

Longevity - Many modern synthetic polymers have a built in superiority in terms of useful lifetime over older materials, and modern additives can further enhance this property. It is an area that the correct compound selection is of vital importance: all rubber based compounds suffer from stress relaxation, i.e the initial sealing force slowly declines during use due to changes in the internal chemistry of the compound, and when the sealing force declines to below a value depending on the application, leaks will ensue.

Plate Heat Exchanger Gasket Materials

For plate (and frame) heat exchangers, the standard materials are EPDM and Nitrile rubber (NBR). EPDM is used normally for non-fatty/oily applications, and NBR for oil/fat applications. However, there are no rules without exceptions. An "oil" and fatty application may have a low fat content, making the application more suitable for EPDM instead of NBR.

Other rubbers used for PHE's are Hydrogenated Nitrile Rubber (HNBR), Fluorocarbon rubber (FKM), Butyl, Chloroprene Rubber (GR), Chlorsulphonated Polyethylene (CSM), Styrene-Rubber (SBR), Natural Rubber (NR) and Silicone Rubber (Q) are less common ones.

All additives matter for the product properties, and not only effect the quality level of the product, they also influence the consistency of the quality level.

Other rubbers used for PHE's are Hydrogenated Nitrile Rubber (HNBR), Fluorocarbon rubber (FKM), Butyl, Chloroprene Rubber (GR), Chlorsulphonated Polyethylene (CSM), Styrene-Rubber (SBR), Natural Rubber (NR) and Silicone Rubber (Q) are less common ones.

All additives matter for the product properties, and not only effect the quality level of the product, they also influence the consistency of the quality level.

Lifetime

Eventually all rubber materials will degrade, loosing their properties, making them unsuitable for further use. It is all a matter of time and the original quality of the product. The lifetime of rubber products is dependent on the environment (chemical types, concentrations) and temperature. Also, temperature changes and pressure changes effect the performance and lifetime of the rubber product.

Chemical Resistance

Each rubber material has its unique resistance towards various chemicals. The polymer used, as well as additives, effect which chemicals each rubber material is suitable for.

High Temperature

At high temperatures the rubber will be attacked faster by the chemicals in use, and the surrounding oxygen. The oxidation process will either make the rubber harder (the most common one) OR make it softer (less common), OR both at the same time. Either way the change in properties will reduce the performance. All rubber materials have a maximum continuous temperature, which should not be exceeded to maintain good performance and to achieve a reasonable lifetime.

Low Temperature

At low temperatures the stiffness increases, and the elasticity decreases. This influences the sealing force of the gaskets. All rubber materials have a certain lowest temperature that have to be exceeded to be able to perform well enough as a gasket.

Food Applications

For food applications there are demands according to national standards. The usual one for PHE gaskets is FDA (USA). This standard regulates what additives are allowed to be used in the rubber and to what content. It also sets demands on what tests have to be done to ensure the quality level.

Rubber properties/Test Methods

Hardness: Measured normally as Shore A or IRH D. Both methods are based on the penetration of a needle into a rubber surface. The less the penetration is, the harder the rubber is.

Tensile Strength: the force needed to break a piece of rubber, Measured in force/cross area unit |

Elongation at break: How much a rubber can be stretched until breaking. Measured in % of original length. Tear strength: How much force is needed to break a rubber sample with a specified crack. Measured in force per thickness.

|

Compression set: The idea of measuring the compression set is that the lower the compression set is, the higher the sealing force is. It is measured in % of the deformation. Heat Resistance/Heat Ageing: is measured through measuring the change in various mechanical properties.

|

Chemical Resistance: Is measured through measuring the change in volume, weight, and various properties. Low temperature resistance: Is measured either through compression set of tensile retraction test, which is a test or elasticity at low temperature.

Condition Audit

Knowing the right time to replace gaskets for critical plate heat exchangers ensures plant reliability, productivity and uptime. That’s what one of the world’s largest ethylene producers in Saudi Arabia discovered after Condition Audit for the company’s 11-year-old gasketed plate heat exchangers.

Many factors affect the operating condition of heat exchangers. Process conditions and heat transfer media, for instance, may change. Opening the heat exchanger frequently also influences heat exchanger performance. These have a direct effect on the mechanical condition of the heat exchanger. “Even if the gaskets are selected to meet design conditions, they can either last longer or require replacement earlier than expected depending on actual operating conditions,”

“Gasket rubber also ages, which affects the sealing force as well as the service life of the plate heat exchanger.”

Preventive maintenance for more uptime

Management at the plant agreed to conduct a Condition Audit on one of the 39 heat exchangers during scheduled maintenance. A Service Engineer was on site when the unit was opened. Condition-based auditing tools were used to analyze the current condition of gaskets and plates as well as actual operating conditions. The scope of work comprised internal and external inspection of the heat exchanger to determine the current condition of its:

• Channel plates, including detailed plate deformation analysis

• Gaskets, including a prediction of remaining lifetime

• Frame, including connection linings

• Bolts and bearing boxes

• Spare parts inventory Long-term service for a long-time customer

The data clearly indicated that the gaskets were approaching the end of their service life, and that reconditioning of the plates was necessary.

Environment affects performance

Gaskets can lose elasticity and sealing capabilities at a faster rate due to operating conditions. For instance, gaskets in plate heat exchangers for applications involving water, especially at low temperatures, can be in service for decades without leaking. On the other hand, gaskets used in the process industry, where plate heat exchangers handle corrosive materials, such as lye and acids, at high temperatures are subject to high stress and wear more quickly.

Choose the right material for the environment

Specific environments attack different types of rubber in different ways. The type of rubber polymer is the most important factor in determining the environmental resistance of the gasket. One formulation may be completely destroyed by a specific environment, while another of the same elastomer type may remain essentially unaffected. Therefore, compatibility predictions must be based on experience with actual plate heat exchanger formulations.

It is important to know the capabilities and limitations of a gasket rubber compound. New gaskets are highly resilient, expanding to seal in the media and to direct flow. Maintaining this condition helps ensure optimum performance. To maximize gasket lifetime: (1) invest in the right type of gasket – one capable of compression in order to resist the stress and force generated by the flow of media, and (2) select the right gasket materials.

Rule of thumb:

10 °C lower than max temperature ==> 2 years lifetime

10 °C above the max temperature ==> 6 months lifetime

|

Thanks for the gasket article! We also carry epdm gaskets, please go here to see what we carry:

RispondiEliminahttps://www.dieandgasket.com/epdm-gaskets-in-phoenix-arizona

This is a informative post which provides the detailed information about the lifetime of a gasket.

RispondiEliminaSpiral wound Gasket

Insulation kit Gaskets

Nice blog About Silicone Gasket. Nice information about gasket. Thank you for sharing.

RispondiEliminaVery Informative,Thanks for sharing

RispondiEliminaSpring Energized PTFE Seals

I am very happy to see this post because it really a nice post. Thanks

RispondiEliminaThank you for your articles that you have shared with us. Hopefully you can give the article a good benefit to us.

RispondiEliminaAflas Gaskets

I really liked your Information. Keep up the good work.This is a really informative knowledge, Thanks for posting this informative Information.

RispondiEliminaEPTFE Gaskets

Nice post thanx for sharing with us.

RispondiEliminaSiddhivinayak enterprises is the one of the best leading manufacturer and supplier of Plate Heat Exchanger supplier in pune,india,Plate Heat Exchanger manufacturer in india,Plate Heat Exchanger exporter in india,Plate Heat Exchanger dealer in pune,Plate Heat Exchanger dealer in india.

Plate Heat Exchanger supplier in pune

Plate Heat Exchanger supplier in india

Plate Heat Exchanger manufacturer in pune

Plate Heat Exchanger manufacturer in india

Plate Heat Exchanger exporter in india

Plate Heat Exchanger dealer in pune

Plate Heat Exchanger dealer in india

Great blog. All posts have something to learn. Your work is very good and i appreciate you and hopping for some more informative posts.EPDM Gaskets

RispondiEliminaThanks for posting the useful information.

RispondiEliminaWe are leading suppliers in Pune, India of separation equipment. Other products are centrifuge separators, plate heat exchanger, milk processing plant, spare & parts

Ghee Clarifier manufacturer in pune

Pasteurizer Gaskets dealer in india

Dairy Equipment dealer in pune

Milk Processing Plant supplier in india

Plate Heat Exchanger Gaskets supplier in pune

Plate Heat Exchanger exporter in india

Electrical Farm Cream Separator manufacturer in india

Farm Cream Separator manufacturer in pune

Ghee Clarifier dealer in india

Edible Oil Centrifuge Separators dealer in pune

Marine Centrifuge Separators supplier in india

Heat Exchanger Plates supplier in pune

Centrifuge separators supplier in pune

Milk Processing Unit exporter in india

Thank you for your articles that you have shared with us. Hopefully you can give the article a good benefit to us.Flexible Graphite Gaskets

RispondiEliminaI accept there are numerous more pleasurable open doors ahead for people that took a gander at your site.

RispondiEliminaEstimates

Nice blog. We are American Seal & Packing and we manufacture great quality Gasket Materials for industries and machinery plants. We offer great packing materials that are perfect for your heavy-duty work. Visit us to know more about us.

RispondiEliminahello sir very nice blog

RispondiEliminaCommercial track lighting

Hanging light for office

Home office ceiling lights

Linear light fixture

Track light price

very nice blog

RispondiEliminaBest data cable

Apple data cable

Fast charging data cable

Fast charging magnetic cable

Type c data cable

Data cable charger

3 in 1 usb data and charging cable

Usb data charging cable

expatriates

This blog post is full of knowledge about beauty nail products. Lets also check our beauty nail Profiles

RispondiEliminaGel Top Coat

Top Coat Gel Uv

Gel Base Coat

Glitter Top Coat

Best Matte Gel Top Coat

No Wipe Top Coat Gel

There is A great Post Created By You !

RispondiEliminaLets Introduce about :-

Fluorocarbon Viton

FluoroSilicone Rubber

Vnsilicones.com

This blog post is awesome. You can also visit us for the silicone products.

RispondiEliminaCustom Rubber Seals

Silicone manufacturer

silicone tube manufacturer

extruded silicone

Hi sir very nice blog

RispondiEliminaThis blog post is full of knowledge about Lathe Machine Cutting Tools inserts products. Lets also check our Lathe Machine

Cutting Tools inserts Profiles.

Grooving Inserts

Turning

Insert

Carbide Insert

Cutting Tool

APKT Insert

Milling Insert

Indexable Carbide Inserts

This blog post is full of knowledge about massager products. Lets also check our massager Profiles.

RispondiEliminaRechargeable battery

Solar battery

Off grid solar system

Lfp battery

Lithium

titanate battery

Lifepo4 batter

Forklift battery

Energy storage system

Thanks for sharing this blog.this blog is very useful.

RispondiEliminaMetal Gaskets

Non-Asbestos Gaskets

Spiral Wound Gaskets

PTFE Gaskets

Hi sir very nice blog

RispondiEliminaThis blog post is full of knowledge about fast-charging-data-cable products. Lets also check our fast-charging-data-cable Profiles.

data cable manufacturer

fast charging data cable price

3 in 1 usb data and charging cable

data cable price

Usb data transfer cable

Fast charging magnetic cable

Hi sir very nice blog

RispondiEliminaThis blog post is full of knowledge about Transformer products. Lets also check our Transformern Profiles.

Static Var Generator

Active Harmonic Filter

Electrostatic Precipitator Power Supply

Pad Mounted Transformer

Compact Substation

Oil Filled Transformer

Magnetron Sputtering Power Supply

Oil Immersed Transformer

Hi sir very nice blog

RispondiEliminaThis blog post is full of knowledge about sofa products. Lets also check our sofa Profiles.

Faux Leather Dining Chairs

Dining Room Sets for sale

Modern Dining Room Table

Fabric Sofa Set

Genuine Leather Sofa

Grey Leather Sectionals

Brown Sofas Living Room

Lounge Chairs for Sale

Questo commento è stato eliminato dall'autore.

RispondiEliminaHi sir very nice blog

RispondiEliminaThis blog entry is brimming with information about sofa items. Lets likewise check our sofa Profiles.

Latex Mattress

Gold Stainless Steel Chair

Stage Wedding Sofa

Grand Father Clock

7 Seat Lounge

Dining Room Cabinet

To get weatherproof Silicone Sealant, just view haohongsealants.com/aluminium-composites-panel.html

RispondiEliminaNice Post!!

RispondiEliminaExcellent resistance to a widely variety of aggressive chemicals which is the using elastomer and TFE/P combination. Aflas Gaskets is known for its use in oil field applications and its high electrical resistance. Aflas has low aromatizing properties making it great in applications with lingering smells.

Think about it, what was the main aim of the cooler or the refrigerator kept in your home? To your food fresh and intact. Well, for all we know, cooling has to be right up top for that. Many a time we notice that our cooler is not cooling properly. Well, it could be an issue of sealing. Buy new cooler gaskets at Refrigaskets Canada.

RispondiEliminaDURASILE is a leading Non Asbestos Gasket Sheets Manufacturers providing high-quality, durable, and eco-friendly sealing solutions for various industries. Our non-asbestos gasket sheets are designed to withstand extreme temperatures, pressure, and chemical exposure, ensuring superior performance and safety.

RispondiEliminaWith 15+ years of industry experience, DURASILE is a trusted Jointing Sheets Manufacturers and a leading producer of Millboards and Gasket Sheets. Known for quality, innovation, and reliability, we serve diverse industries including petrochemical, automotive, thermal power, and process sectors. Our advanced manufacturing processes and skilled team ensure products that meet the highest performance standards. DURASILE is committed to delivering durable and effective sealing solutions tailored to customer needs.

RispondiEliminaAira Trex Solutions India Pvt Ltd is a trusted name in industrial solutions, serving as SMC Pneumatics Brand Cylinder Suppliers, Norgren Brand Solenoid Valves Suppliers, Honeywell Transmitter Suppliers, Parker Directional Control Valve Suppliers, and Eaton Bussmann Fuse Suppliers with quality and reliability.

RispondiElimina