Midstream/ Downstream Processing Schemes

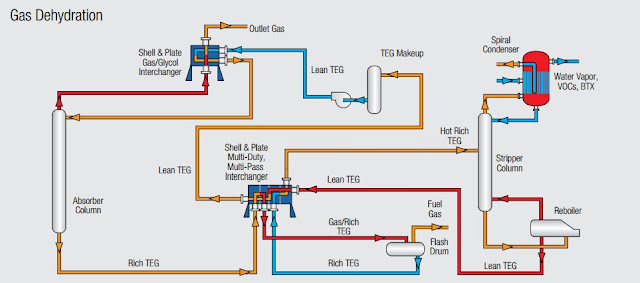

Gas Dehydration. A PSHE unit with a three-pass/two-pass, countercurrent arrangement heats two cold-side, rich TEG streams in one unit. The exchanger provides better energy recovery and reduces the size of the reboilers used in the skids. The welded unit has also resulted in a more compact skid structure and no tube bundle pulling deadspace.

Compression Intercoolers And Lube Oil Coolers. PSHE Coolers provide precise control of compressor suction temperature and increases in overall compression efficiency; gasket-free compressor PSHE Lube Oil Coolers withstand pressure spikes and reduce volume of expensive lubricants.

Gas Sweetening. Single-pass welded units are used as a lean amine cooler and as a lean/rich amine interchanger. The small draw depth facilitates close temperature approach, reducing external energy requirements. The unit can accomplish 90%-plus heat recovery from lean to rich amine, or with sulfinol. A spiral unit provides easy maintenance as an amine reboiler.

Propane Recovery. A PSHE reduces temperature to condense more propane and heavier components and attain target gross heating value. Installed downstream of the chiller, the unit improves propane recovery significantly without additional refrigeration. The compact unit can fit on existing skids without additional support structures.

Demethanization. A Shell & Plate exchanger functions as a low side heater on a demethanizer column, using -37°C (-35°F) propane to raise the methane-rich gas from -59°C (-75°F) to -41°C (-42°F). With its low pressure drop, the PSHE is attractive for use as a partial or total reboiler in cryogenic service, with improvements over brazed aluminum units in withstanding thermal shock.

Alkylation. Shell & Plate units offer significant opportunities for improving thermal efficiency and response in the alkylation process. They perform well as condensers on reactor, deisobutanizer, debutanizer and depropanizer columns; as preheaters and reboilers; as steam generators.

Distillation. Heat from cooling and condensation on distillation columns can be recovered through either PSHE(shown) or Spiral units. A PSHEor Spiral can function as an efficient partial reboiler. The excellent performance to size/weight ratio saves in support structures and maintenance.

Hydrodesulfurization And Catalytic Reforming. Untreated naptha/jet fuel is preheated using surplus heat from off gas, desulfurized product and raw reacted product. A Spiral preheats reacted product for the stripper column using stripped desulfurized product as a heat source. Finally, Spiral or PSHE units condense the lighter distillates. Thermal efficiency is higher than with S&T units.

Coking. Spiral units serve as a coke drum feed preheater and as a fractionator reheater. Additional spiral units handle duties as a fractionator condenser and in heat recovery. Other welded units can serve as a gas oil fraction cooler.

Solvent Deasphalting. Spiral units function as low maintenance interchangers for feed/oxidized bitumen and asphalt/oxidized asphalt. They also heat solubilized stripped asphalt for reinjection into the extraction tower. PSHE exchangers function well in the vapor-phase processing of deasphalted oil, as interchangers and heaters.

Vis-breaking (Thermal Cracking). Cracked residue contains considerable heat energy that can be recovered for preheating by Spiral exchangers. PSHE units can undertake preheating duties using the gas oil fraction. PSHE units are also effective as coolers of the light distillate vapor.

Fluid Catalytic Cracking. Spiral units improve response and efficiency as an overhead condenser/makeup water heater, as a bottom fraction cooler, as a clarified slurry oil cooler and as fraction coolers for several products.

Read complete article on

http://www.tranter.com/literature/markets/hydrocarbon-processing/oil-gas-brochure.pdf

Thanks for the great details mentioned in the blog , It is helpful blog for downstream process schemes.

RispondiElimina

RispondiEliminaGreat Blog! This post gives a better idea. Thanks for the useful information. I hope you will share some more content. Please keep sharing! propane gas prices

Very well explained, loved your content

RispondiEliminahttps://www.nirmal.co.in

Nice articles and your information valuable and good articles thank for the sharing information Thermal heat exchanger performance

RispondiElimina