Air Cooler Trouble Shooting

Air Cooled Heat Exchangers (ACHE for short) are units that are in frequent use across the process and energy industries. These are essential exchangers that plants rely on for heat rejection into the atmosphere.

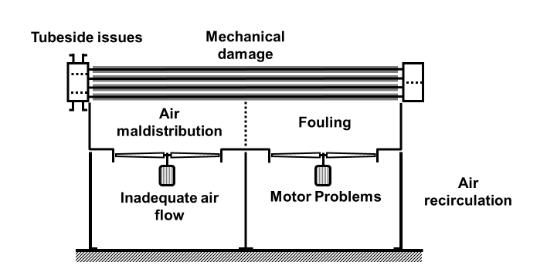

At the moment underperformance of ACHEs is fairly widespread across a variety of industries, and the high level expertise required to diagnose these issues is fairly scarce. Several factors can contribute to an underperforming air cooler, each one of these root causes can manifest itself in a number of ways, with some of the following as examples:

- Flow Maldstribution

- Inadequate ground clearance

- Wind effects

- Fin damage

- Undersized motors

- fouling of fan blades

These and further issues contribute to underperformance of air coolers in many industries.

CALGAVIN offers a consulting service that can be tailored to suit your plant’s requirements. We implement this service through a structure that is broadly represented in the following three steps:

1.IDENTIFY THE ROOT CAUSE

This is carried out through a combination of desktop analysis and modelling, as well as detailed site surveys. Desktop analysis consists of using computational fluid dynamics in detail to model existing cooler conditions, and see if there are any immediately visible problems in the bundle in relation to flow and distribution.

In addition to this detailed on site surveys can be carried out through engineers that have had over 15 years of experience with air cooler operations. This will allow the analysis of further potential problems, such as cleaning techniques or examination of damaged air seals/partition plates. On site smoke tests can also be carried out for further analysis.

2. QUANTIFY THE PERFORMANCE PROBLEM

After the process simulation through CFD and other modelling techniques and site surveys are carried out, CALGAVIN engineers will compile a comprehensive report on the problems identified. This will include evaluations of heat loss and resulting performance reduction, to enable clients to clearly understand how these problems are affecting their processes and plant economics.

This report can determine the most efficient course of action by exploring possibilities for improvement either through adjusting existing equipment or potentially suggesting new designs. These avenues will be reseached and considered by engineers with extensive experience in these fields, with the client constraints on cost, plot space, duty and further features all having determining effects on what will be analysed for improvements.

3. SPECIFY AND IMPLEMENT SOLUTIONS

Upon review with the client and determining the best courses of action, CALGAVIN will then specify which solutions will best meet the client needs. These solutions will then be installed and implemented, with CALGAVIN providing supervision throughout installation for any solutions.

A performance review will then be carried out, allowing the client to clearly establish what benefit has been acheived from the solutions provided. This quantifying of results will improve understanding of plant performance and help further in development of future processes and increasing efficiency of existing plants.

Commenti

Posta un commento