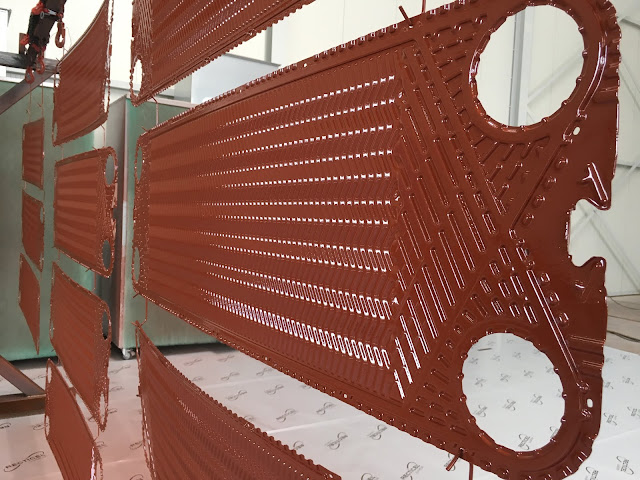

Coating of heat exchangers

Heat cured phenol epoxy coating:

A heat exchanger is a very important part of the chain in a process, it is therefore essential to ensure reliability and optimum performance; To achieve this, a good conservation is required. Years of experience in the field learns us that CP PHENOLICS® coating (phenolic epoxy coating) has outstanding characteristics in this matter.

CP PHENOLICS® heat cured coating achieves great value to customers due to high chemical resistance to aggressive media even in high concentration and high temperatures up to 220°C.

This CP PHENOLICS® coating prevents corrosion , fouling and incrustation in the tubes, therefor operational costs are reduced. The heat conductivity remains constant with the result of better efficiency and allows a simple cleaning process.

This CP PHENOLICS® coating prevents corrosion , fouling and incrustation in the tubes, therefor operational costs are reduced. The heat conductivity remains constant with the result of better efficiency and allows a simple cleaning process.

Benefits of a coated shell tube:

Treatment of the shell tube with CP PHENOLICS® coating will lead to:

- Low resistance coefficient (max. flow through the tubes)

- Optimal heat transfer

- High operational reliability

- Extended lifetime of the heat exchanger

Application description:

The coating is a thermosetting coating of minimum 3 layers. Every layer gets an oven treatment on a different time and different temperature schedule. During the final polymerization session the coating layers cross link with each other on molecular level. Derived from this the coating offers high-end corrosion protection against all sorts of aggressive substances.

Cost reduction:

The aforementioned cases ensure that investment and maintenance costs will be reduced. We therefore recommend not only to provide a protective coating on new heat exchangers but also those heat exchangers who are in actual use.

Example case at Project BASF:

Entry temperature of condensate: 98 – 103 °C, cooling water speed: 0.3 m/sec.

Conclusion:

Due to the absence of protective coating, there was a reduced heat transfer of more than 60% in 36 months!

Commenti

Posta un commento