TOP 7 REASONS TO PURCHASE A PLATE-AND-FRAME INSTEAD OF A SHELL-AND-TUBE HEAT EXCHANGER (Part2)

3. REDUCED MAINTENANCE

High-quality plate-and-frame heat exchangers can operate efficiently for ten years without maintenance. Plates are easy to access for inspection or cleaning in place. Cleaning intervals depend on amounts of fouling or scaling.

Plate heat exchangers are much easier to maintain and operate than shell-and-tube because they’re easier to take apart and inspect. You can easily remove plates for service or repair, whereas shell-and-tube models are more labor-intensive and harder to access internally.

Product buildup or scale coating on surfaces reduces the heat exchanger’s thermal efficiency. Because of plate and frame exchangers’ smaller, modular design, they are faster and easier to clean than larger shell-and-tube units.

4. FOOTPRINT IS SMALLER

5. EXPANDABILITY

Fig. 4. Adding plates to a PHE decreases pressure drop, while adding passes increases pressure drop.

6. CAPITAL EXPENSE

Cost of ownership is always a critical factor in the decision-making process. A plate heat exchanger is the lowest cost option because it can achieve high heat transfer coefficients — with pure counter current flow — giving the most efficient heat transfer and lowest surface area. Maintenance cost is also reasonably low, especially compared to scraped-surface heat exchangers. The main expense is the replacement of gaskets and, occasionally, of plates.

The close temperature approach, meaning a cold fluid being heated to a temperature that is very close to the temperature of the entering hot fluid, allows more regeneration and heat recovery, making a plate heat exchanger a good option. Smaller temperature variances between product and media also prevent burn-on in products with moderate to high sugar or protein content.

In addition to the capital expense for the equipment, capital costs can include shipping, handling, installation, and maintenance over the unit’s lifetime.

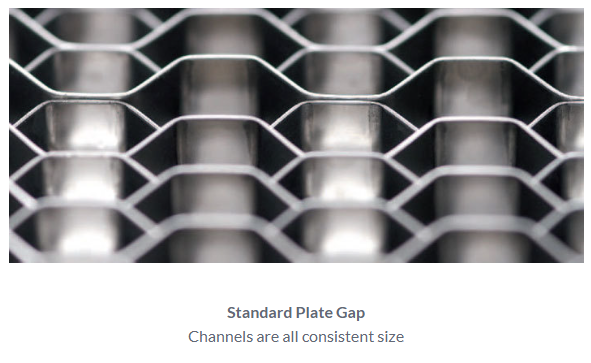

7. TYPES OF PLATES

Plate and frame heat exchangers can be adapter for a variety of product viscosities.

- For viscous products, PHE requires proper plate selection.

- For products with particulate, PHE requires a special plate with low contact points and/or wider gap.

In cases when a PHE has difficulty handling viscous products, it’s typically because it was initially designed for use with fluids of very low viscosity but later used with highly viscous product.

PHE can be adapted to more viscous or particulate products with the exchange of standard-gap (3-5mm) chevron plates for wide-stream plates for fine particulate (same gap but fewer contact points than chevron plates), or wide-gap (up to 8mm) plates that can process larger particulates and higher viscosity. Fig 3. illustrates a range of PHE and plate gap choices by product fiber length, pulp density, and viscosity.

~ Melissa Fryer, Sanitary Heat Transfer Business Development Manager, Alfa Laval

SUMMARY: ADVANTAGES AND DISADVANTAGES OF PLATE AND FRAME HEAT EXCHANGERS

ADVANTAGES

- Relatively inexpensive compared with other designs

- Excellent CIP-ability

- Easy to clean and maintain

- High heat regeneration

- High turbulence

- Replaceable gaskets

- Easy to increase/decrease capacity

- Smaller footprint than shell-and-tube designs

DISADVANTAGES

- Relatively low operating temperature

- Maintenance cost due to gaskets

- Not for use with products of very high viscosity or with very large particulates

Thank you so much for this fantastic content!!.. For more updates you can feel free to go through our website: Heat Exchanger

RispondiEliminaThanks for sharing this! I would like to thank for this...Go through our website also: 48vdc air conditioner

RispondiElimina