Corrugated Tube Heat Exchangers (CTHE): Monotubes-Multitube-Tripletubes when to use

Monotubes-Multitube-Tripletubes XTube® CTHE's are designed and fabricated to suit sanitary and non- sanitary applications.

If the process is sanitary all product side surfaces are polished to ensure a surface roughness Ra ≤ 0.8 μm. And the connections are those typical in the food, dairy and beverage industries.

Special care if taken when pharmaceutical processes are involved as the surface roughness demanded has lower values 0.25-0.4 μm (by electropolishing), seamless tubes and special sterile flanges or clamps.When non-sanitary conditions surface roughness is not an issue but high mechanical resistance, high temperatures and pressures, and corrosive.

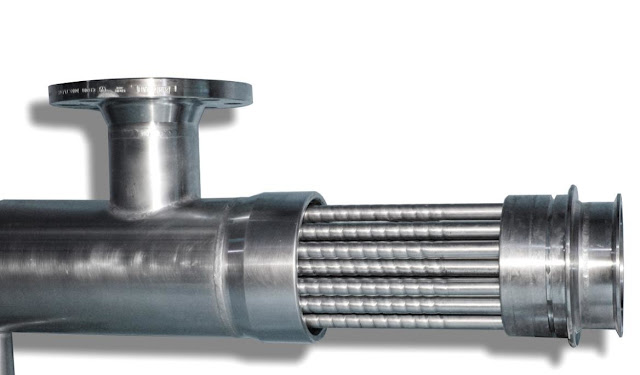

Monotube geometry that is formed by tube-in-tube models

Three geometries to process a vast type of products from low to averange and viscous products, also with particles or solids in suspension like fibers, dices

Xtube® Monotube is used to process products under sanitary and non-sanitary conditions: Fluids with solids in suspension from small to big size (corrugated tubes can be up to 210 mm in diameter). Particulated products (products in pieces).

Xtube® with Multitube geometry can be used sanitary and non- sanitary applications. There are 3 families of multitubes:

XTube® B-Type for Industrial Applications (non-sanitary).

XTube® Multitube for sanitary applications in the Food, Dairy etc industries. Product side surfaces are polished to ensure a surface roughness Ra ≤ 0.8 μm.

XTube® Pharmagrade for pharmaceutical and biotech. Product side surfaces are polished to get a surface roughness Ra ≤ 0.25-0.4 μm.

Why Corrugated Tubes

Xtube® Corrugated Tubes increase the turbulence in the flow thus enabling a more effective mixing and agitation that generates a higher heat transfer coefficient than smooth tubes at the same conditions. Higher U-values means a smaller heat exchanger. Furthermore, corrugation carries a "selfcleaning" effect that reduces fouling on the tube surface. Less fouling means smaller heat exchanger and longer production cycles.

Therefore Heat Transfer Specialists when you have to design a unit with high viscosity fluids consider CTHE in alternative with Spiral Heat Exchanger SHE or Shell&Tube HE's!

Credits to XLG Individual solutions for your industry

Commenti

Posta un commento