In order to achieve optimum process operations, it is essential to use the right type of process equipment in any given process. Heat exchangers, commonly used to transfer energy from one fluid to another, are no exception.

The selection of the proper type of heat exchangers is of critical importance. Selecting the wrong type can lead to sub-optimum plant performance, operability issues and equipment failure.

The following criteria can help in selecting the type of heat exchanger best suited for a given process:

- Application (i.e. sensible vapor or liquid, condensing or boiling)

- Operating pressures & temperatures (including startup, shutdown, normal & process upset conditions)

- Fouling characteristics of the fluids (i.e. tendency to foul due to temperature, suspended solids ...)

- Available utilities (cooling tower water, once through cooling water, chilled water, steam, hot oil...)

- Temperature driving force (i.e. temperature of approach or cross and available LMTD)

- Plot plan & layout constraints

- Accessibility for cleaning and maintenance

- Considerations for future expansions

- Mechanical considerations such as: 1) material of construction; 2) thermal stresses (during startup, shutdown; process upset and clean out conditions); 3) impingement protection

Shell-and-tube heat exchangers accounts for more than 50% of all heat exchangers installed. However, in many cases, there are more attractive alternatives in terms of cost and energy recovery. Any time a heat exchanger is being replaced, the opportunity should be taken to re-assess if the type used is best for the given process. Operating changes since initial installation as well as advancements in the field of heat transfer may point towards a different type as being optimal.

Heat Exchangers Types

Shell & tube heat exchangers

Baffle types

Segmental baffles

Double segmental baffles

No-tube-in-window (NTIW) baffles

Rod baffles

EM baffles

Helical baffles

Tube Enhancements

Twisted tubes

Low finned tubes

Tubes inserts (twisted tapes, Cal Gavin)

Compact type heat Exchangers

Plate & frame heat exchangers (gasketed, semi-welded, welded)

Spiral

Blazed plate & frame

Plate-fin heat exchanger

Printed circuits

Air-cooled heat exchangers

Heat Exchangers Selection

Past experience, is always the best place to start to guide the selection of heat exchanger types. Understanding the reasons behind both successes and failures will lead to better equipment selection.

When comparing different types of heat transfer equipment, one must take into consideration the total cost of the equipment which includes:

- purchase cost

- installation cost

- operating cost (pumping, fan…)

- maintenance cost

In order to make the best selection, it is important to have some knowledge of the different types of heat exchangers and how they operate. The tables below offer the advantages and disadvantages of common types of heat exchangers. They can be used to arrive at a type that is best suited for a given process.

| Shell & tube heat exchangers |

| Advantages | Disadvantages |

| Widely known and understood since it is the most common type | Less thermally efficient than other types of heat transfer equipment |

| Most versatile in terms of types of service | Subject to flow induced vibration which Can lead to equipment failure |

| Widest range of allowable design pressures and temperatures | Not well suited for temperature cross conditions (multiple units in series must be used) |

| Rugged mechanical construction - can withstand more abuse (physical and process) | Contains stagnant zones (dead zones) on the shell side which can lead to corrosion problems |

| Subject to flow mal-distribution especially with two phase inlet streams |

| Compact Heat Exchangers |

| Advantages | Disadvantages |

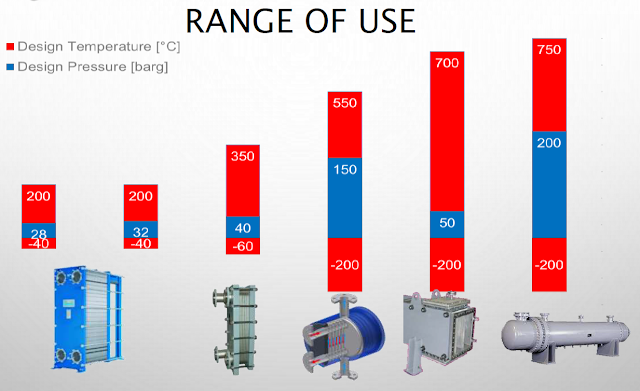

| Low initial purchase cost (plate type) | Narrower rage of allowable pressures and temperatures |

| Many different configurations are available (gasketed, semi-welded, welded, spiral) | Subject to plugging/fouling due to very narrow flow path |

| High heat transfer coefficients (3 or more times greater than for shell & tube heat exchangers, due to much higher wall shear stress) | Gasketed units require specialized opening and closing procedures |

| Tend to exhibit lower fouling characteristics due to the high turbulence within the exchanger | Material of construction selection is critical since wall thickness very thin (typically less than 10 mm) |

| True countercurrent designs allow significant temperature crosses to be achieved | |

| Require small footprint for installation and have small volume hold-up | |

| Air Cooled Heat Exchangers |

| Advantages | Disadvantages |

| Attractive option for locations where cooling water is scarce or expensive to treat | High initial purchase cost |

| Well suited for cooling high temperature process streams (above 80oC when using cooling water should be avoided) | Require relatively large footprint |

| Low maintenance and operating costs (typically 30-50% less than cooling water) | Higher process outlet temperature (10-20 oF above the ambient dry bulb temperature) |

Nice Information. Galaxy Industrial Equipment - Top Heat Exchanger Manufacturer In India, according to our international and domestic customer specifications. Our heat exchangers are made of high quality steel with high structural strength and long service life.

RispondiEliminaFor More Information Visit: http://www.galaxyprocess.in/heat-exchange.html

Excellent and decent post. I found this much informative, as to what I was exactly searching for. Thanks for such post and please keep it up. Heat Exchanger Manufacturer in India | High Speed Disperser Manufacturer in India | Mechanical Circulator

RispondiEliminaGood and informative post describe all details of high speed disperser manufacturers. Thanks for post excellent post.

RispondiEliminaGreat article! I’ve been researching different cooling systems lately, and I found your insights very helpful. In industrial applications, especially in hydraulics and heavy machinery,aircooledoilcoolers play an important role in maintaining temperature stability and preventing equipment breakdowns. Your explanation made it much clearer how they work in real-world scenarios. Looking forward to reading more of your posts!

RispondiElimina