Semi-welded Plate Heat Exchangers (SWPHE): Advantages in critical media applications

Typical applications of Semi-welded Plate Heat Exchangers

Refrigerant evaporator

- Evaporation of refrigerant on the welded side in order to cool the media on the gasketed side.

Evaporation of heat transfer fluid in geothermal power plants

- Evaporation of ammonia on welded side with the heat from geothermal water on the gasketed side.

Economical alternative to FKM / PTFE-PHEs

- Only FKM / PTFE-O-rings needed.

- High security due to reduced gasket-length by 90%.

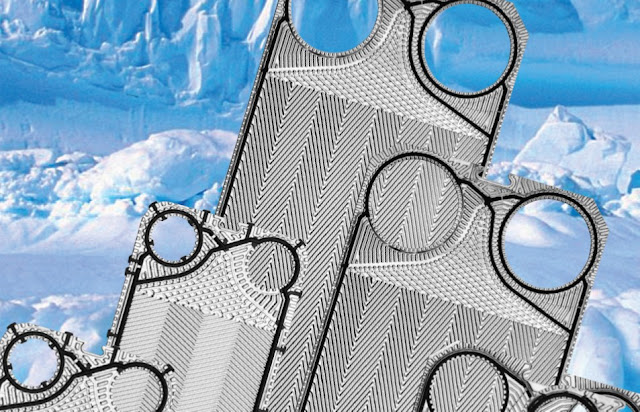

Cassettes created with coupled plates

Media flowing in cassette in contact only with o-ring gasket

Media flowing in cassette in contact only with o-ring gasket

Semiwelded typical Advantages

- Gasketed side can be inspected and cleaned as normal gasketed PHE plates

- Sealing length with gasket reduced to 20% (ring gasket) à Risk of leakage reduced by 95%

- High flexibility due to exchangeable modules. Extensions of PHEs can be done easily.

- Existing gasketed PHEs can be redesigned to semi-welded

- No spare parts on welded side needed à faster ROI

- Investments lower compared to gasketed PHEs FKM / PTFE

Therefore Heat Transfer Specialists when you have to design an Heat Exchangers in severe conditions, before to move to Shell& Tube HE's, Bloc Type or Shell&Plate HE's start to consider a Semi-welded PHE as valuable option!

Happy calculations!

Commenti

Posta un commento